How to Identify High-Quality Water-Resistant Sandpaper Abrasives?

In applications such as grinding, polishing, and metal finishing, the quality of water-resistant sandpaper abrasives directly impacts grinding efficiency and workpiece precision. Many buyers struggle with inferior products—either the abrasives shed and clog the paper, or the water resistance is poor, ultimately increasing material costs. Identifying high-quality waterproof sandpaper abrasives isn't complicated; mastering a few key methods makes selection straightforward.

First, examine the abrasive material

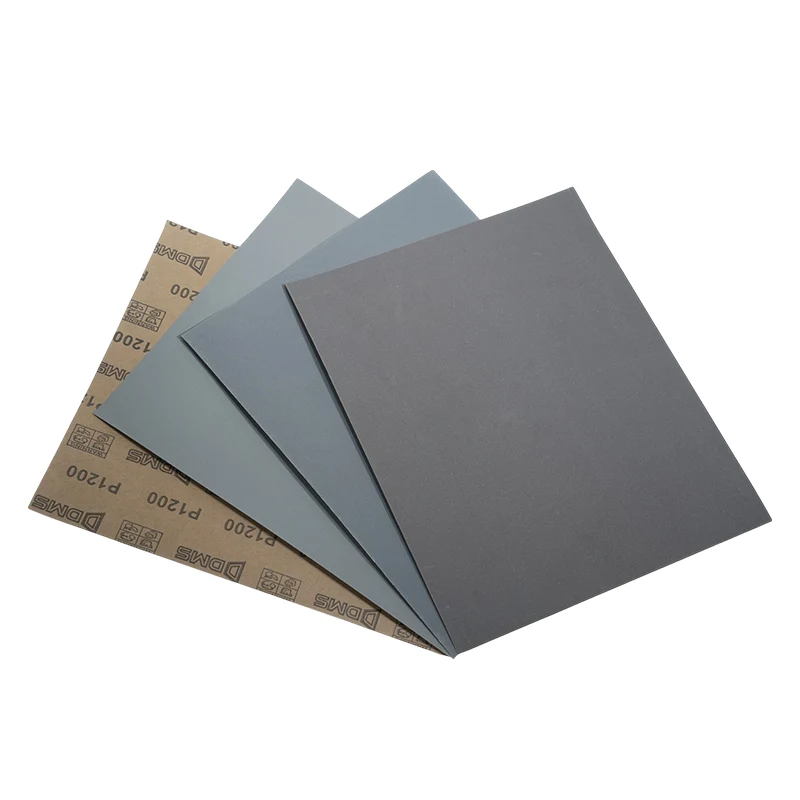

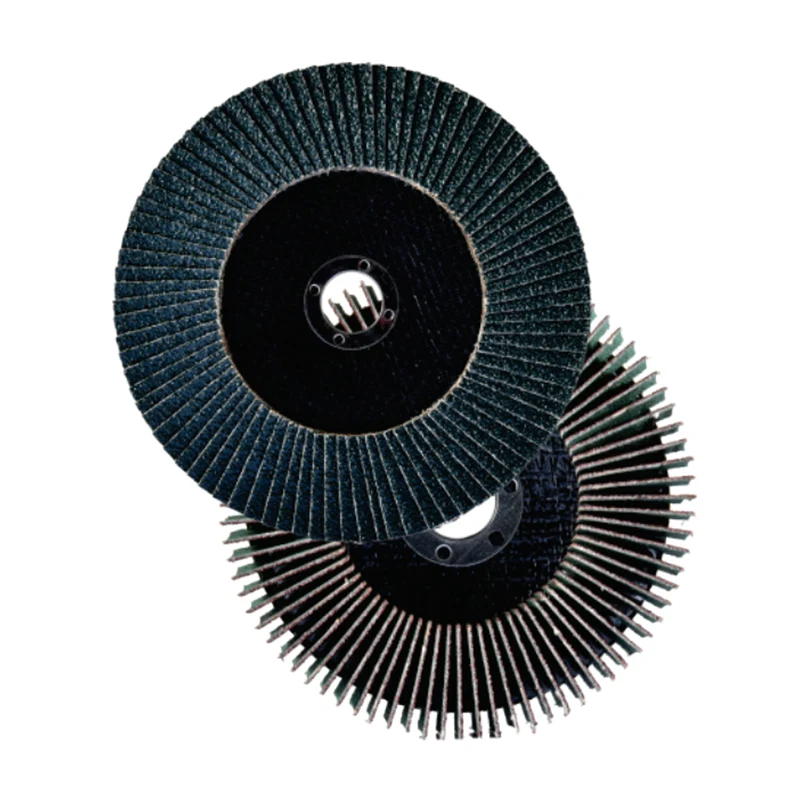

Premium waterproof sandpaper typically uses high-performance abrasives. These feature high hardness and toughness, remaining sharp and wear-resistant without fracturing during grinding. Examine the sandpaper surface: premium abrasives exhibit uniform coloration—commonly appearing in rich brown, creamy white, or black hues. Gently rub the particles between your fingers; they should feel hard and resist powdery shedding. Inferior abrasives display mottled colors, shed debris easily when rubbed, and feel coarse and loose.

Second, assess particle uniformity

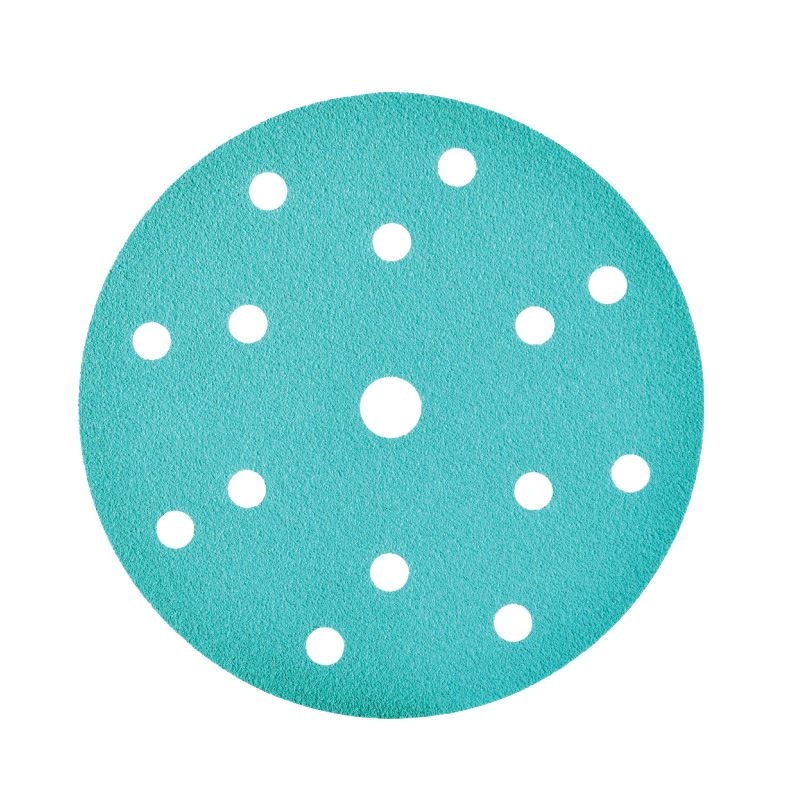

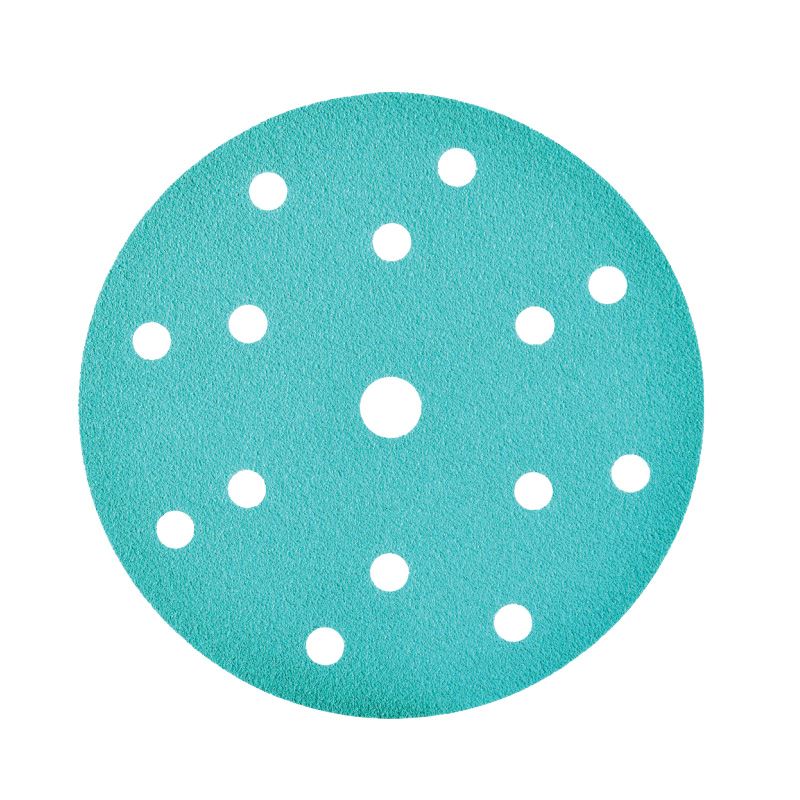

The uniformity of abrasive particles directly affects the smoothness of the sanded surface. Lay the sandpaper flat under bright light: high-quality sandpaper shows neatly arranged particles without localized denseness or sparseness. Particles should be similar in shape, with minimal irregular needle-like or flake-like debris. Sandpaper with uneven particles tends to leave inconsistent scratches on the workpiece surface during use.

Finally, test water resistance

Water resistance is a core characteristic of this type of sandpaper. High-quality abrasives are firmly bonded to the backing and will not delaminate or shed when exposed to water. Take a small piece of sandpaper, soak it, then gently rub the surface. A quality product will not experience large-scale abrasive loss, and the backing will not wrinkle or deform. After drying, touch the surface—the abrasives should remain securely attached.

In summary, mastering these methods—examining material composition, assessing uniformity, and testing water resistance—enables quick identification of high-quality water-resistant abrasive paper. Paying attention to these points during selection helps avoid substandard products, ensuring you choose sandpaper suited to your needs. This approach enhances processing results while reducing costs.

About DMS:

As a manufacturer specializing in high-quality coated abrasives, DMS products are widely used in automotive manufacturing, metalworking, wood processing, and industrial production. Leveraging a vertically integrated production system and continuous R&D investment, DMS is committed to delivering innovative, customizable abrasive solutions that meet the evolving application needs of global professional users.

- How Are Net Abrasives Redefining Surface Preparation Standards Across Industries?

- How to Select Metal Grinding Discs for Stainless Steel and Aluminum?

- How Does a Hand Sanding Block Improve Surface Quality and Support the Future of Manual Finishing?

- How Masking Tape Innovations Are Improving Surface Protection in Modern Manufacturing?

- Introduction to artificial abrasives.

- Classification of grinding tools.